01. Die Bonding

Secure silicon dies onto customized substrate surface per customer needs.

Capable of handling many special dies (e.g. MEMS dies) with proven processes

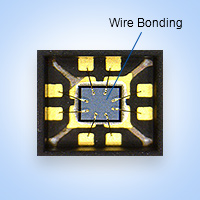

02. Wire Bonding:

Make the fine-pitch wire connector between silicon dies to the outside world.

Capable of prototyping unique wiring path and special surfaces.

03. Optical Coupling

Align fiber to the designated position to ensure optimal performance.

04. Mems Device Customization

Specilized in MEMS chip package, optical design and control integration, e.g. MEMS optical switch

05. Device Assembly

Develop and implement optical module and equipment assembling process based on customized requirements.

Procure standard and customized components on behave of end customers.

06. Equipment Testing

Measure electrical and optical parameters to verify the specification compliance.

Conduct standard environmental tests per customer's specification.